-

Call Us Now +86-576-81116176

-

Send Mail To info@aicmould.com

milk crate mould is our main plastic injection mould in the plastic mould town of China, especially for bottle crate mould, fish crate mould, vegetable crate mould, industrial crate mould, milk crate mould, fruit crate mould, bread crate mould and others. we have high experience in solid crate mould and foldable crate mould.

Our Advantage of:

1.Customized mould making according to customer's requirements

2.Experienced group for part&Mould design

3.On-time delivery

4.Advanced Equipment

5.One-year-warranty for each mold

As one of leading crate mould manufacture, AIC mould had experience on making injection mould for more then 10 years. The classification of plastic injection crate molds is milk crate mould, plastic bread crate molds, injection fish crate moulds,high precision industrial crate molds, special design collapsible crate moulds, 12 bottles & 24 bottles crate mould. ect.

Precision milk crate moulding is done with the help of the state of the art technology. Experienced tool maker like us could meet the needs of buyers. Automatically milk crate mould with help of applied robotic and inspection process, a high efficient milk crate moulding manufacture line will save labor cost for buyers.

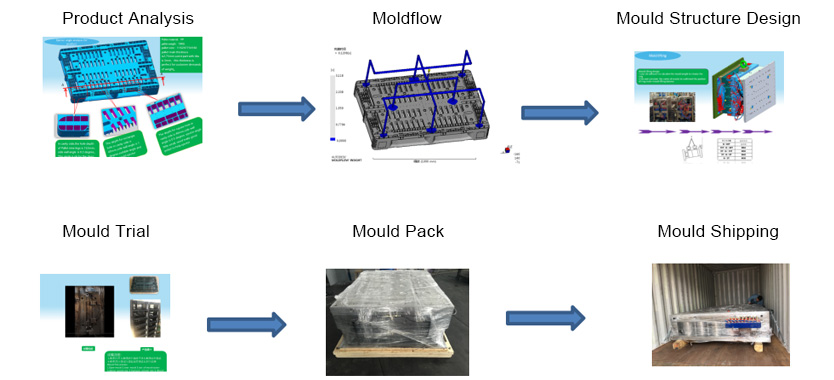

So how the milk crate mould will be process? And which is the carefully point for a high quality milk crate mold?

1. 2D& 3d part drawing need supply by buyers for get detail quotations and mould technical details. If buyer need copy existence crate samples, exhaustive size and picture for various of detail need supply. Mould undercut and any design link to mould sliders need to be clearly.

2. Milk crate mould design: after receive the advance payment of mould, Product drawing will be checked by technical team. DFM report will be supply to customer before make mould drawing. DFM report will included crate mould rough size, planning ejector methods, mould sliders or mould lifter position ( if have).Most important is does there any part design are not suitable for crate mould construction.

3.How to choose the crate mould machining way is very important point for final result of high quality mould. High precision CNC machine will be the best choice for high quality crate molds.

4.Cooling system, Exhaust system and guiding system is 3 carefully point. Plenty and average cooling channel will help cooling faster. Use B-copper to some place of milk crate mould will also help cooling. A experienced designer could make a perfect exhaust system. Guiding system need a high precision machining to make sure the mould running smooth.

Whatever milk crate mould or other special crate mould, the unique characteristic decide this product will wide range used.If you have any interesting for crate projects,AIC mould here supply you best mould solution.

Please leave your Email or phone nomber, so we can contact you as soon as possible.